Case Study: How Rush save $1 million in Supply Spend

Read our latest case study to discover how Rush University Medical Center, an academic medical center with over 600 beds located just outside of Chicago, used Owens & Minor’s QSight to transform how they managed their inventory.

Learn how Rush leveraged the power of QSight and the deep visibility into inventory levels it provides to save over $1 million in OR supply spend. Find out how they used QSight to change their clinical workflows, making life easier for clinicians and giving them time back to spend more time with patients.

Read more by filling out the form.

Read more by filling out the form.

QSight® takes care of managing healthcare inventory so that clinicians can take care of patients.

Rush University Medical Center is an academic medical center with over 600 beds. Named a top U.S. hospital by U.S. News and World Report, Rush is nationally ranked fifth in adult specialties and rated high performing in three adult specialties and six procedures and conditions.

The Challenge

Efficient Medical Inventory Management

Like a lot of hospitals, Rush relied on manual processes and work-around solutions to manage inventories in different departments like the OR and their Cath Lab. Rush was able to make it work, but it was a laborious process, eating up a lot of staff time and didn’t provide any actionable data. “We had very limited visibility into our supply chain,” said Nicholas Scrutchions, Rush Supply Chain Operations Manager.

Rush could only look at data for products that cost over $500, and that data was not timely and required adjustment before it was usable. There was no visibility into basic information such as product-level detail, inventory dollar value, or where in the hospital to replenish inventory. The results were predictable: high costs, excessive inventory, and products scattered in locations all around the hospital.

Lack of visibility wasn’t the only problem that Rush faced in managing inventories. They also faced issues with expired and recalled products. “You would have to physically touch everything to know if it was expired or not, so supply chain techs used to spend roughly three to four hours a day cycle counting,” said Scrutchions. “There wasn’t a system in place.” Rush staff had to manually update a list every time they learned of an expiring or recalled product. “There was no way to track recalled items or product expiration that didn’t involve a manual process.”

The system Rush was using wasn’t just hard on the supply chain staff; it was hard on the clinicians as well. Clinicians were having to manually record items after they were used in a procedure. Not only was it time-consuming and taking away from patient care, the process was error prone, from not recording a product used in a procedure to recording the wrong product. “Clinicians don’t have time to monitor inventories. They want to spend their time on patient care,” said Jeremy Strong, Vice President, Supply Chain Operations, at Rush. “As a result, recording errors ensued, resulting in excessive amounts of inventory, risk of expiration, higher cost, waste, and obsolescence.”

The leadership at Rush knew there was a better way to gain more control over supply costs and allow clinicians to care for their patients without worrying about inventory. They needed an inventory management system.

The Solution

Rush involved the clinical team early in the selection process. Bringing clinicians in early generated collaboration on every level. The team discussed their inventory workflows and how an inventory management solution could support them. “We involved clinicians in the decision process from the beginning,” said Scrutchions. “They were able to see how a solution would not only fit into their existing workflow, it would also make it flow more smoothly.” Rush realized they needed an end-to-end solution from a partner that was flexible, nimble and whom they could work with. They chose Owens & Minor’s QSight as the solution.

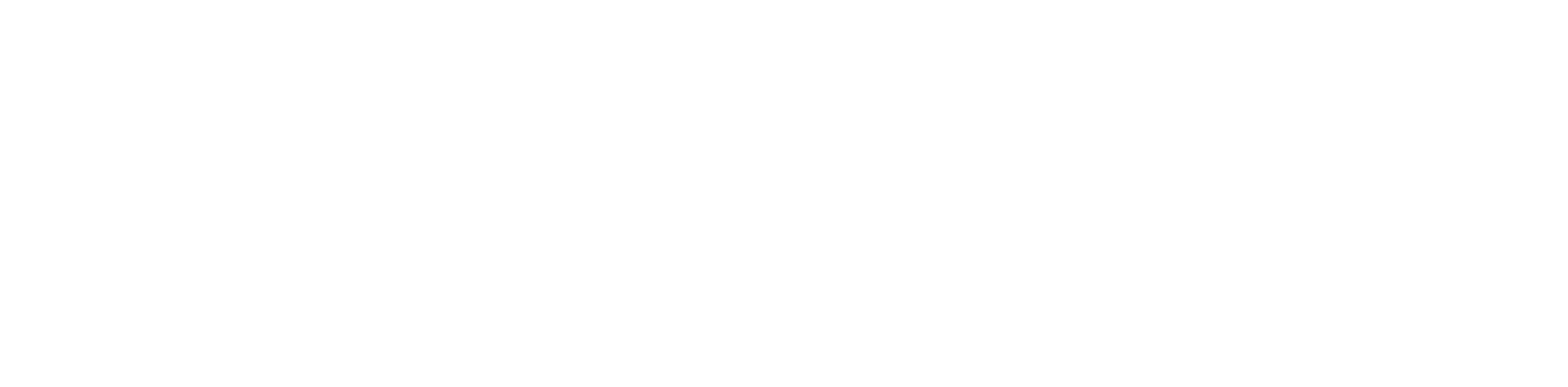

QSight is a cloud-based, end-to-end inventory management solution for operating rooms, cath labs, electrophysiology labs, interventional radiology, and ambulatory surgery centers. With a single scan of the manufacturer’s bar code, QSight captures critical information about the product, updating inventory levels, clinical documentation and sending charge codes for billing, eliminating the need for manually keying in information.

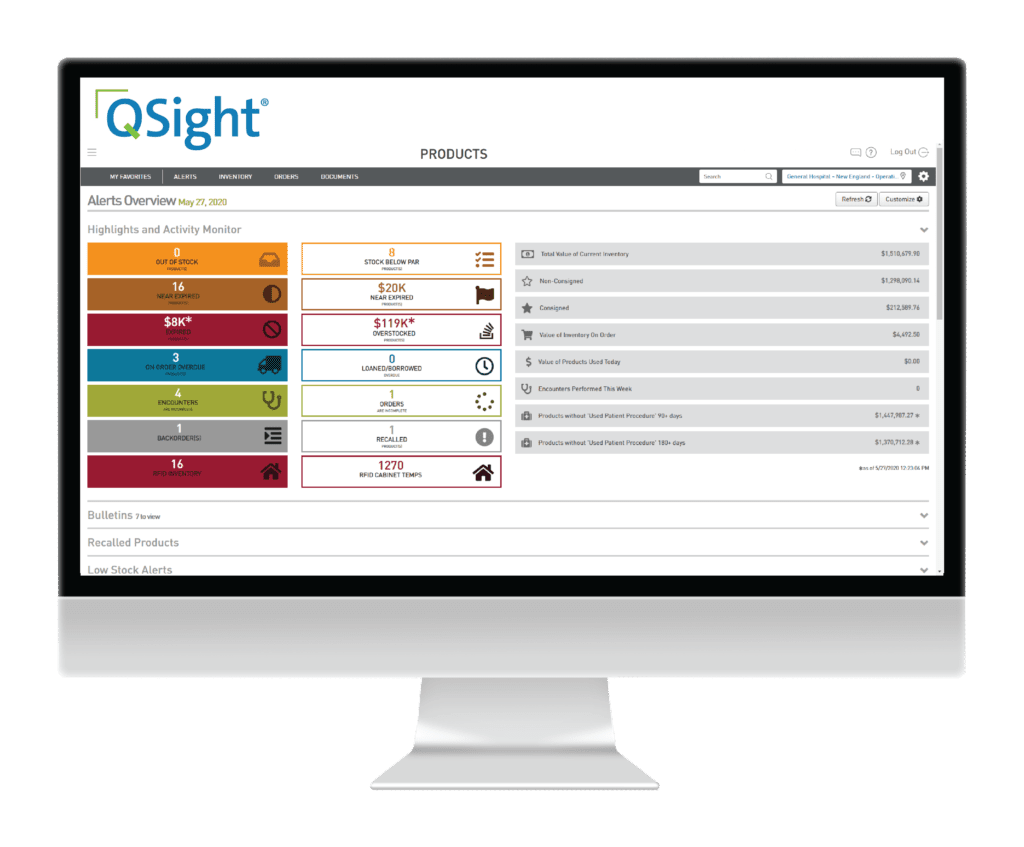

The real power of QSight, however, is what it does with all that data. With easy-to-use dashboards and powerful reports, QSight users have instant access to critical supply information, like inventory levels, items below PAR, items on order, expiry, obsolescence, and value of products. Armed with this information, QSight users gain more control over their inventory, simplifying and optimizing it while minimizing spend.

Implementation

90 Days to Go-Live

Implementing any software solution, especially a medical inventory management solution that could impact patient care, can be a daunting task. However, that task was made much easier with the dedicated QSight implementation team that worked side-by-side with Rush every step of the way. Rush was able to implement QSight within 90 days starting first with seven Interventional Radiology Labs, two Electrophysiology Labs, and two Non-Invasive Ventilation Labs. Then, taking advantage of the scalability of the platform, they rolled it out across the OR department including 36 ORs.

Customization

Two Features Requested by Rush

Rush requested two customized QSight enhancements to help improve the clinical workflow.

Serialized Barcodes

The first was a serialized barcode that would be pre-printed on a colored label and placed on each product. This colored label would provide a visual indicator of which barcode to scan on a product that might have multiple barcodes. This enabled a single scan and prevented the scanning of the wrong barcode.

Seamless inventory transfers between departments

The second enhancement was the ability to seamlessly transfer inventory between the Interventional Radiology (IR) and OR departments to better optimize inventory management. With this enhancement, a product that is assigned to the IR inventory but used and scanned in a procedure in the OR is automatically depleted from the IR inventory. This enables IR to seamlessly maintain an accurate inventory count while allowing the staff in the OR to document the instance without disrupting the clinical workflow.

The QSight team worked closely with Rush to build these enhancements into QSight. And Rush isn’t the only one to benefit from them. Because QSight is cloud-based with a single software code base, these new enhancements are also available to other QSight customers.

The Results

Reducing O.R. Supply Spend by Over $1 Million

QSight has dramatically changed every step of the inventory process at Rush University Medical Center. For the first time, Rush now has visibility to point-of-care information by product, location, and physician. With this data, Rush has been able to cut costs out of the supply chain without impacting the quality of care or the clinical team.

Now when a product comes to Rush, it is scanned into the system using a hand scanner. Once scanned, QSight captures critical information about the product including, description, lot number, expiration date, and where the product is stored. Then once the product is used in a procedure, a clinician scans the product again, automatically decrementing it from inventory. And because QSight is integrated with Rush’s EMR system, EPIC, the use of the product is automatically captured into the patient’s implant log within EPIC. “Not only did QSight integrate seamlessly with our EMR and ERP, it also fit into our clinician’s workflow naturally, saving them hours of time that they can now put back toward our first priority: our patients,” stated Strong.

With all of this information captured by QSight, Rush now has a complete picture of their inventory and supply chain. Using QSight’s easy-to-use dashboard, Rush can see in an instant not only information such as total inventory dollar value (owned and consigned), how much of a product is on hand, and the value of inventory on order, but critical and time-sensitive information such as number of products nearing their expiration date, recalled products, obsolete inventory, and so much more. With this information and deep insight, Rush is able to easily make decisions on what products to order, when to order them, and for which location.

Ordering products has also gotten easier for Rush. With QSight, Rush can now aggregate requisitions by manufacturer to streamline purchasing activities and reduce the number of purchase orders.

Results at a Glance

Expired and recalled products are easier to handle as well. Utilizing QSight’s 600,000 SKU database, Rush has set QSight to trigger an alert to staff when a product is set to expire in three months. The staff are then able to use QSight to quickly locate where the product is stored and ensure it is either used or pulled before the expiration date. Locating recalled products “once took about 45 minutes to an hour, if staff could access all the rooms; now it takes about five minutes,” Scrutchions said.

Rush has used the powerful reporting capabilities of QSight to dive deeper into their supply chain than they ever have before. Supply chain staff is now able to pull reports for vendors that track product by lot and serial number for implant replacements. The PAR recommendation report has helped Rush optimize inventory by automatically adjusting PAR levels, up or down, to ensure they have the right inventory in the right quantity at the right location at the right time. For high velocity items Rush orders frequently, they were able to leverage analytics to review usage history in order to set the optimal PAR level and prevent overstock. Armed with this information, Rush now can easily identify and address slow-moving or obsolete inventory that hasn’t been used on a patient in 90, 180, 270+ days.

The results have been impressive. Rush was able to reduce inventory by over $900,000 and reduce OR supply spend by $1 million. But there were more intangible benefits of using QSight. “QSight gave us the data analytics we needed to be efficient without the need to bring on more FTEs, or disrupting the workflow of our clinicians,” stated Quincy Stanley, Associate Vice President, Supply Chain Operations. “Perhaps even more importantly, QSight has made life a little easier for the people around here and ultimately contributed to better patient outcomes.”