An easier way to manage consumables in the procedural area

Consumables, those smaller items like tubing, syringes, and adhesives, are an important part of any procedural area. But all too often, they are treated as an afterthought. What usually results is too much inventory, stored in too many places, with too much of it wasted. That’s why we created QSight Kanban.

Designed specifically with procedural areas in mind

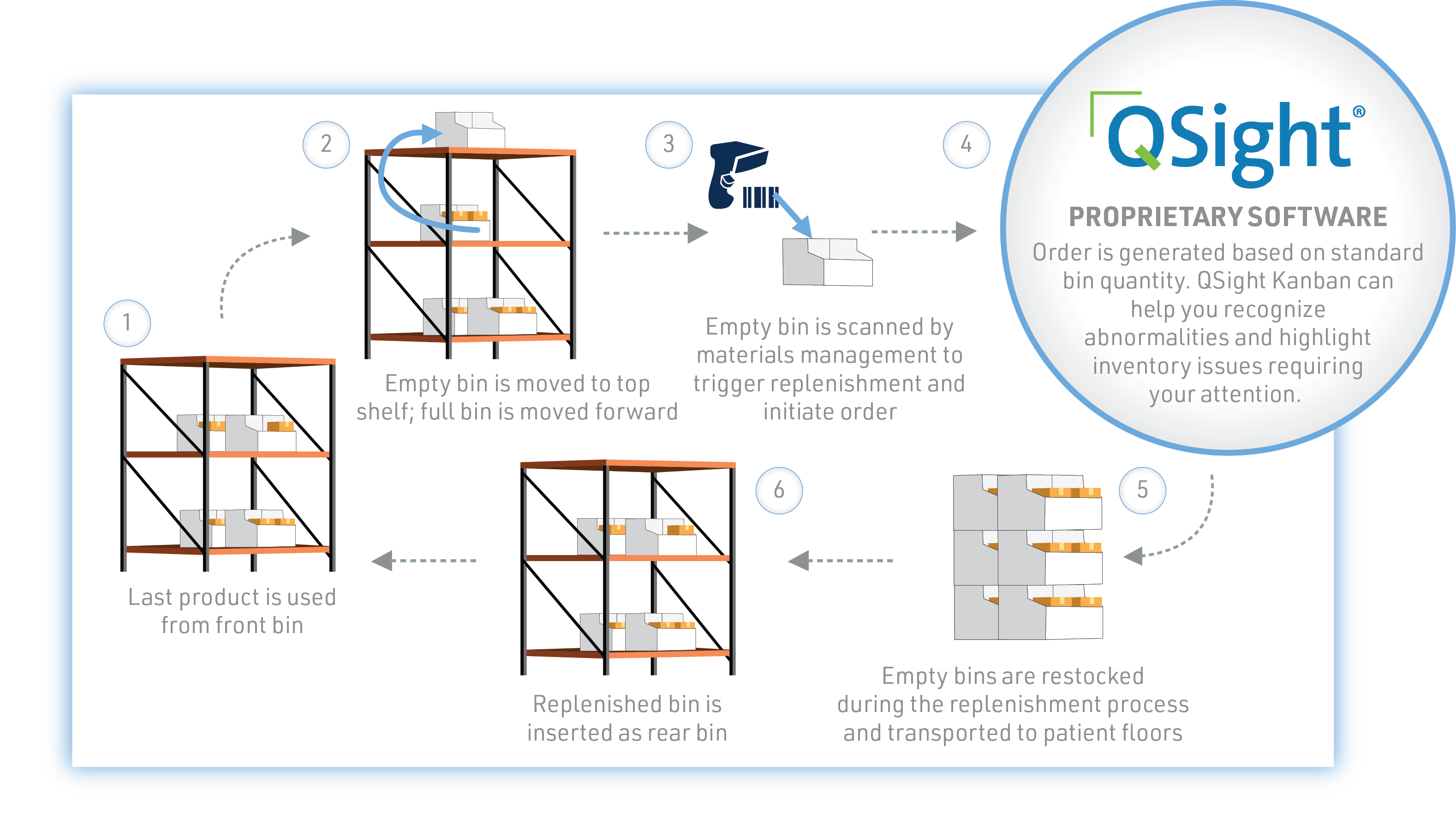

Kanban is an easy-to-use two-bin solution to manage the inventory of your consumables in procedural areas of the hospital. It uses visual cues to inform you of when to order replenishment inventory and hand-held scanners that scan a bin’s barcode to reorder product.

A QSight Module

Kanban is a module of QSight, Owens & Minor’s cloud-based inventory management solution for procedural areas. Featuring an easy-to-use interface, QSight combines real-time visibility of inventory levels, items on order, backorders and much more with powerful analytics tools that turn data into actionable information via enterprise dashboards. The result is a solution that puts you in control of your inventory, driving down your costs and improving your efficiency.

How it Works

Quick and Easy Implementation